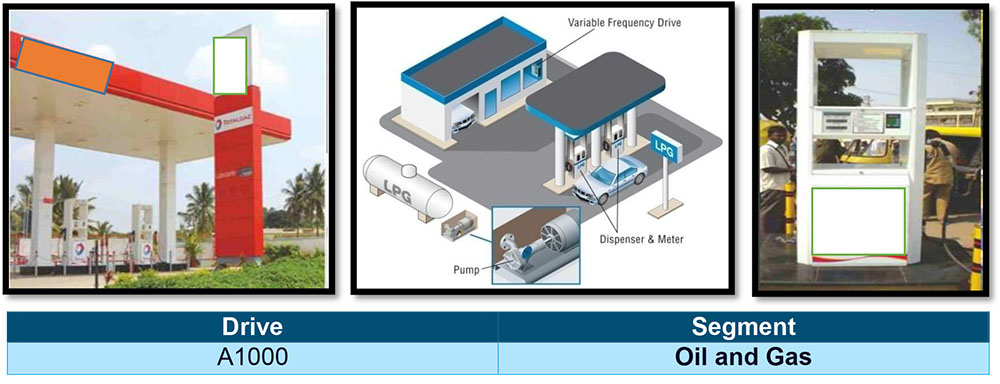

LPG Pump Motor

Auto gas is the common name for liquefied petroleum gas (LPG) and when it is mixed with air, a highly flammable mixture is produced. The flammability range is between 2 % to 10 % by volume of gas to air. LPG vapour is also heavier than air, therefore any release will migrate to the lowest point where it will concentrate and form a highly flammable

mixture.

Challenges

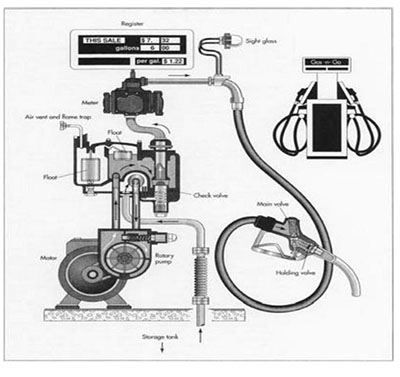

Pumps are used in gas filling stations to unload the gas into the storage units and

dispensing the gas into the refilling units such as automotive vehicles. During the

process of unloading and dispensing, the

pump motor runs at full speed – 50Hz.

Whilst unloading full speed of pump was

ok, but same not desirable during

dispensing, as small quantity of LPG fills up

to customer’s vehicle tank in no time – may

be a fraction of a second. Thus most of the

time customer’s suspect on quantity filled in

the customer vehicle tank. Also due to

frequent on-off sequence failure of

contactors was high.

Solution

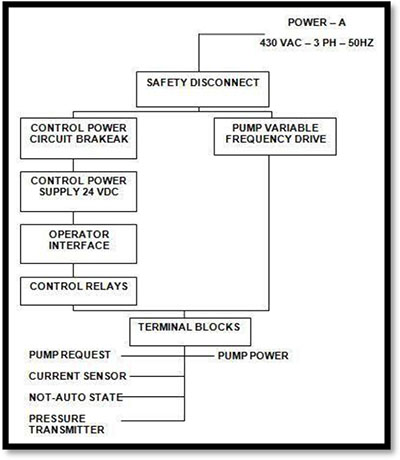

VFD is incorporated to run the pump motor in such a way that during unloading the gas

into the storage unit motor rotates at high speed - frequency 60/75 Hz so that unloading

time is reduced. Similarly, at the time of dispensing, motor rotates at slow speed with

smooth start – acceleration time 15 sec and speed 20 HZ - so that gas filling in to

customer vehicles tank is increased.

Product Supplied

AC Drive : YASKAWA A1000

Power Rating : 5.5kW,400V,3ph

Application : LPG Pump Motor

Benefits

By using YASKAWA Variable Frequency Drives in above controller some important

benefits to for fuel transfer systems:

- Easy, reliable and smooth operation process.

- Reduce peak current hence motor efficiency increases.

- Energy saving, YASKAWA drives utilize only the energy necessary to accomplish the task.

- There is no additional controller or PLC required for the individual control.